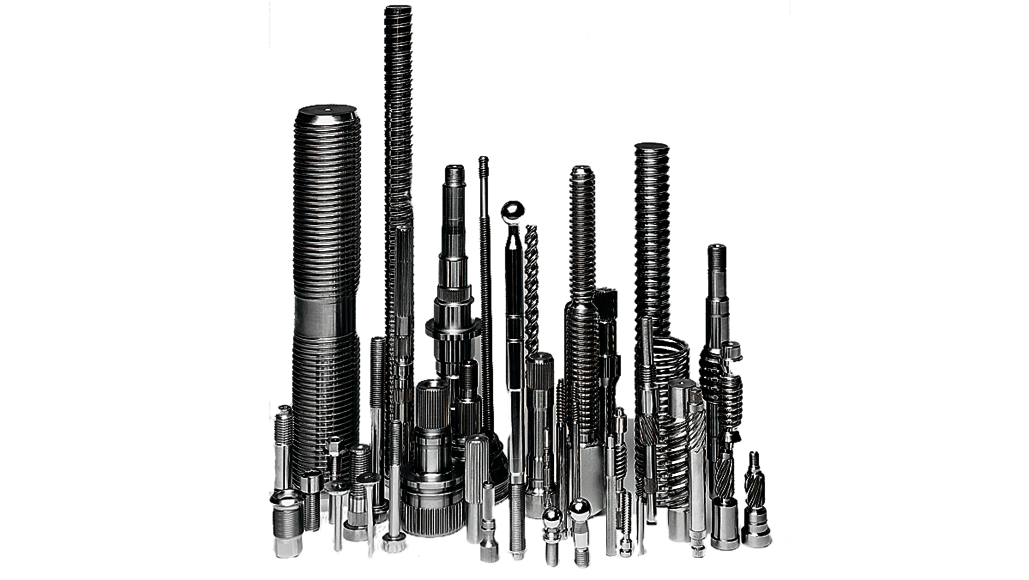

Thread rolling and profile rolling machines

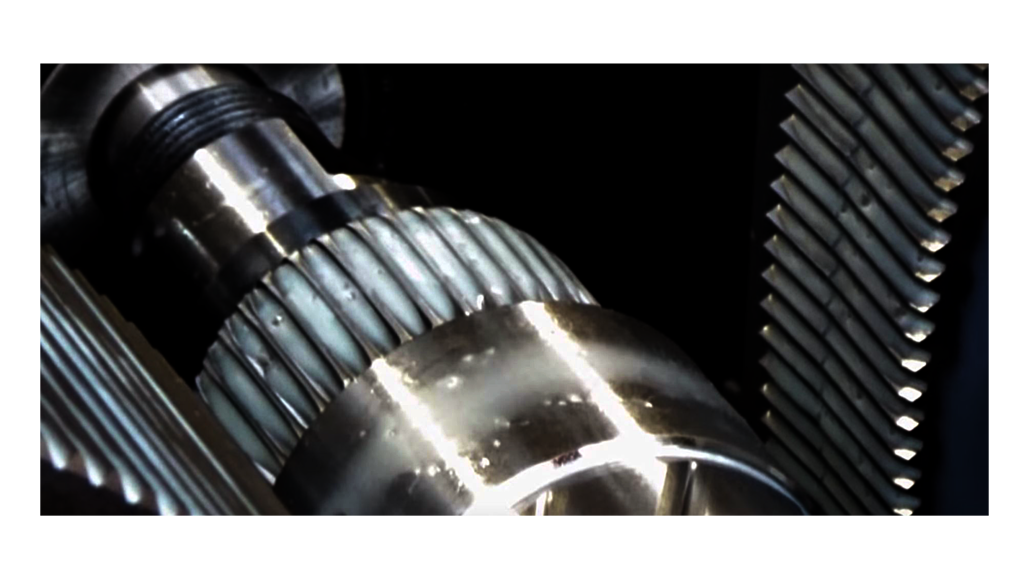

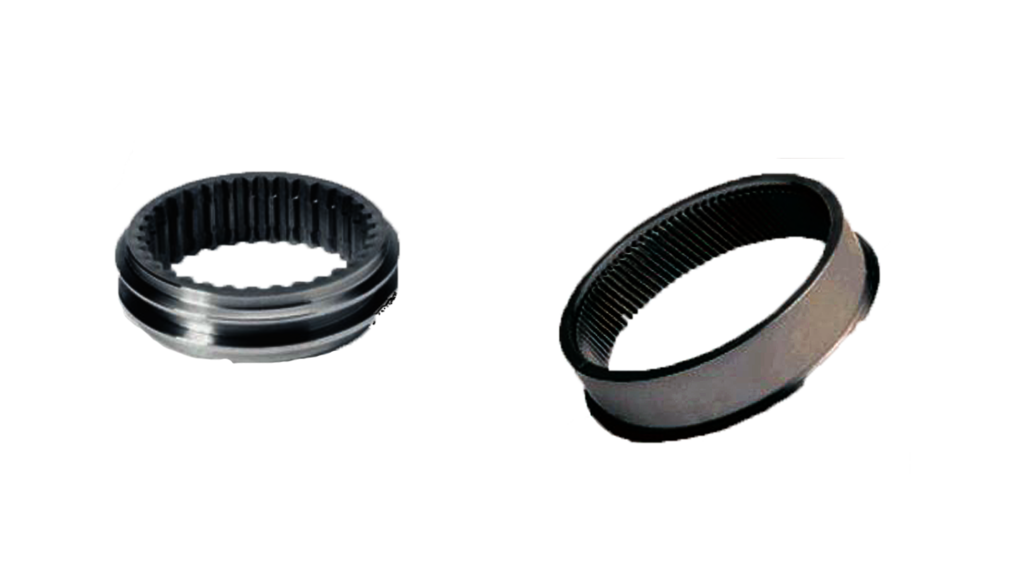

Innovations and decades of experience enable the development of rollable profiles far beyond standard threads. The resulting profile rolling machine of modern type is now indispensable in today's manufacturing.

Thread rolling, thread rolling, and profile rolling on machines made by Profiroll offer the latest innovations in the highest quality.